Engineer with Passion

Personal Tasks

-

Design, build, and compete with a robot

-

Lead a team of 10 students through the engineering process

-

Build relationships with sponsors

-

Develop detailed CAD part & assembly models of the entire robot

Hard Skills

-

PTC Creo Parametric

-

Programming

-

Mechanical design principles

-

Simple circuits

-

Trouble-shooting of code and mechanical problems

-

Metalworking tools

-

Technical presentations

-

2D drawings

-

Budgeting

-

Bill of materials

Soft Skills

-

Engineering process

-

Leadership

-

Teamwork

-

Planning

-

Communication

-

Problem-solving

-

Troubleshooting

Freshman year of high-school I was invited to join a robotics team. The following year I founded my own much more competitive team in which I spent up to 100 hours/week learning key skills that gave me a head-start in college. In university, I spent one semester on the school's Vex robotics team as a mechanical consultant.

The Robots

The Freshman robot did not perform well and is hardly worth mentioning except that it inspired me to do better.

Robot #1: "The V"

Competition goal: Place plastic doughnuts on a PVC rack faster than your opponents

Awards:

-

1st place out of 30+ teams in 2 consecutive competitions

-

Podium finish at Maryland State Championship

-

Think Award - for creative & successful problem-solving

-

Judge's Award (2x) - for team sportsmanship

Personal contributions:

-

Overall team leadership

-

Detailed design of all mechanical arms, lifts, & pulleys

-

Troubleshooting & improvement of all mechanical systems

-

Construction of most mechanical systems

-

Team branding & website

-

Systems design & layout

-

Placement of sensors

Favorite story:

We strongly expected to lose our first competition. We were inexperienced and our robot looked less fancy than our opponents. Our first match was supposed to be a 2v2, where each team is assigned another team as a partner. Our partner was a no-show, so we competed 2v1 and managed to win by more than double the other team's score. The same exact thing happened during our second match. We went undefeated for the entire competition and won 1st place, qualifying for States. A few weeks later we went undefeated at a second qualifying competition, double-qualifying for the state tournament. This was very rare for a first-year team.

SlideShow:

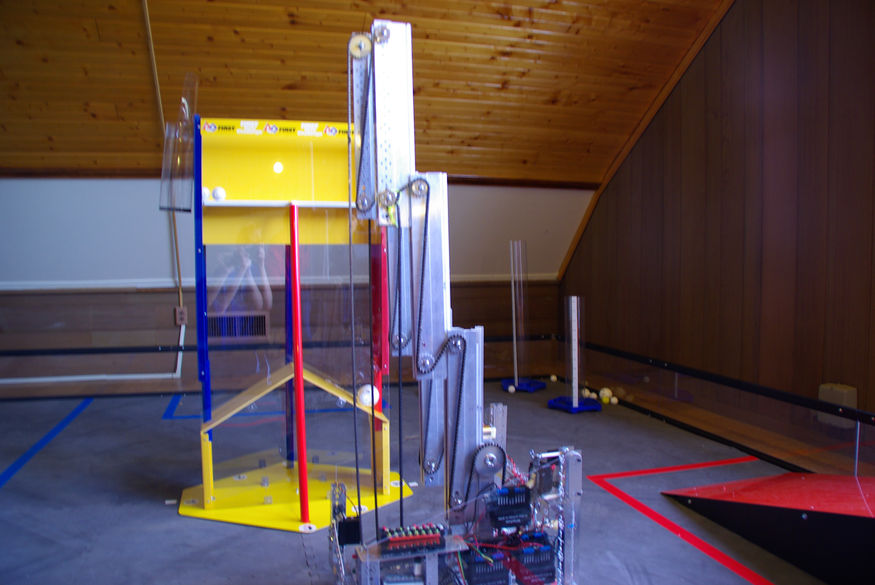

Robot #2: "The Vacuum"

Competition goal: Collect plastic cubes from the ground and place them in crates swaying on a teeter-totter. Extra points to any robots hanging from a pull-up bar at the end of the match.

Awards & Achievements:

-

1st place out of 30+ teams in 2 consecutive competitions

-

Semi-finalist (2x) out of 60+ teams in state and regional-level competitions

-

Qualified for world championship

-

Inspire award for all-around robot performance

-

PTC Design Award for best CREO models (2x), as the only CAD user this year I consider this my award

-

Out of the 72 teams at Worlds, our autonomous program was the only one we observed to work with 100% reliability

Personal contributions:

-

Overall team leadership

-

PTC CREO model of the entire robot

-

Detailed design of mechanical arms, lifts, & pulleys

-

Programming of autonomous code

-

Troubleshooting & improvement of all mechanical systems

-

Construction of most mechanical systems

-

Team branding & website

-

Systems design & layout

Favorite story:

There were 2 parts to the competition, an autonomous and a user-controlled portion. Our user-controlled program scored enough points that we did not bother to compete autonomously at all. I decided we needed an autonomous program to compete at the international level, so I coded in the car while we drove to the world championship at St. Louis. The program nearly worked the first time I tested it on a practice-field, and after spending 5 minutes tweaking just 4 variables, it worked with 100% reliability. I did not see that level of consistency from even the tournament champions.

SlideShow:

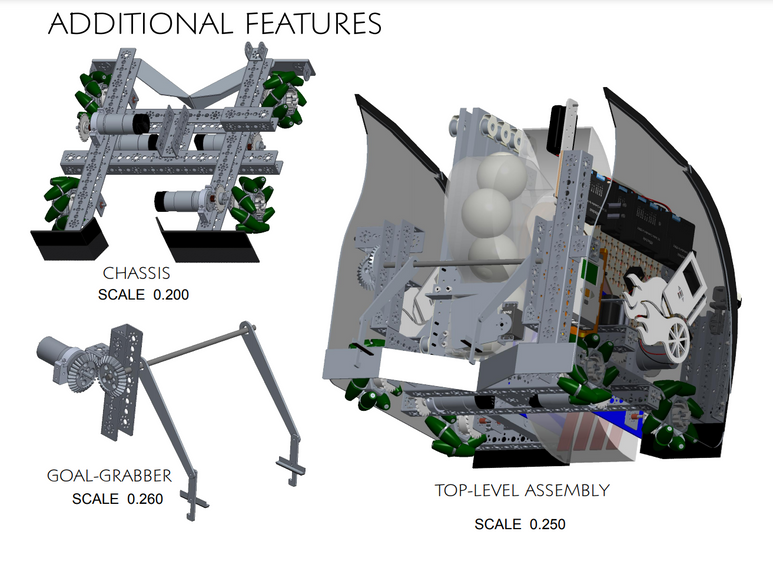

Robot #3: "The Failure"

Competition goal: Collect plastic balls of varying size and place them in tall mobile tubes. Taller tubes award more points.

Why we failed and why it was my most important experience:

Given our prior successes I attempted to build a robot that could accomplish all competition goals. The robot was to max out all possible points in the game with time to spare, and was to do it all autonomously if remote communications failed. The robot was intended to triple its height and remain that tall for the entire competition, and it was to have a ball-launcher to toss balls through the air into the goals. We were too prideful to realize this was beyond our skill-level, budget, and tooling capabilities. Up until this point we had never failed, and it is important to fail because that is how we learn most. These hard lessons helped me be a better engineer in college and the workforce.

Lessons learned:

-

Simple designs are better when possible, do not over-engineer!

-

Be humble

-

Keep goals realistic

-

Design in-budget

-

Design for manufacturability

-

Schedule realistically and hold to it

-

Perform assembly collision detection

-

Keep timeline in mind

-

Do not become emotionally attached to designs

-

When necessary, be prepared to re-design entirely

-

Past success does not guarantee the future, be critical

New skills obtained:

-

Learned how to research materials

-

Learned CREO better than ever

-

Learned to design new parts from-scratch for additive manufacturing

-

Learned several new manufacturing techniques

SlideShow:

Robot #4: "Redemption"

As a final project for a design class, I re-designed the previous robot from-scratch. This was my first solo design and it implemented:

-

More robust CAD techniques as taught by my aerospace mentor

-

More original parts than before

-

A manufacturing and assembly plan

-

Detailed wire routing

-

Motion simulations and component collision detection

-

Robust geometric calculations

-

Revision control

-

Part drawings

5 years later I am still convinced this design would not only have worked, but would have been highly competitive. The following slideshow contains excerpts from my final high-school report:

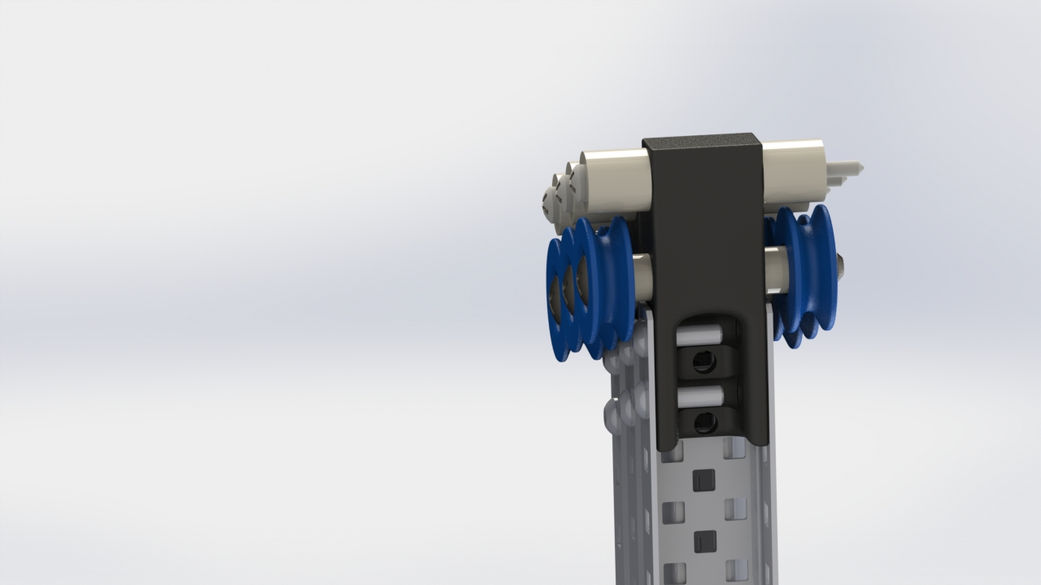

College Robotics

The VEX Robotics team at Liberty University asked me to design for them a lift similar to the one I designed in Robot #4. I was glad to see my untested high-school concept, which was by then 3 years old, worked beautifully.